Blast Furnace Lines Piping Project

Blast Furnace Lines Piping Project

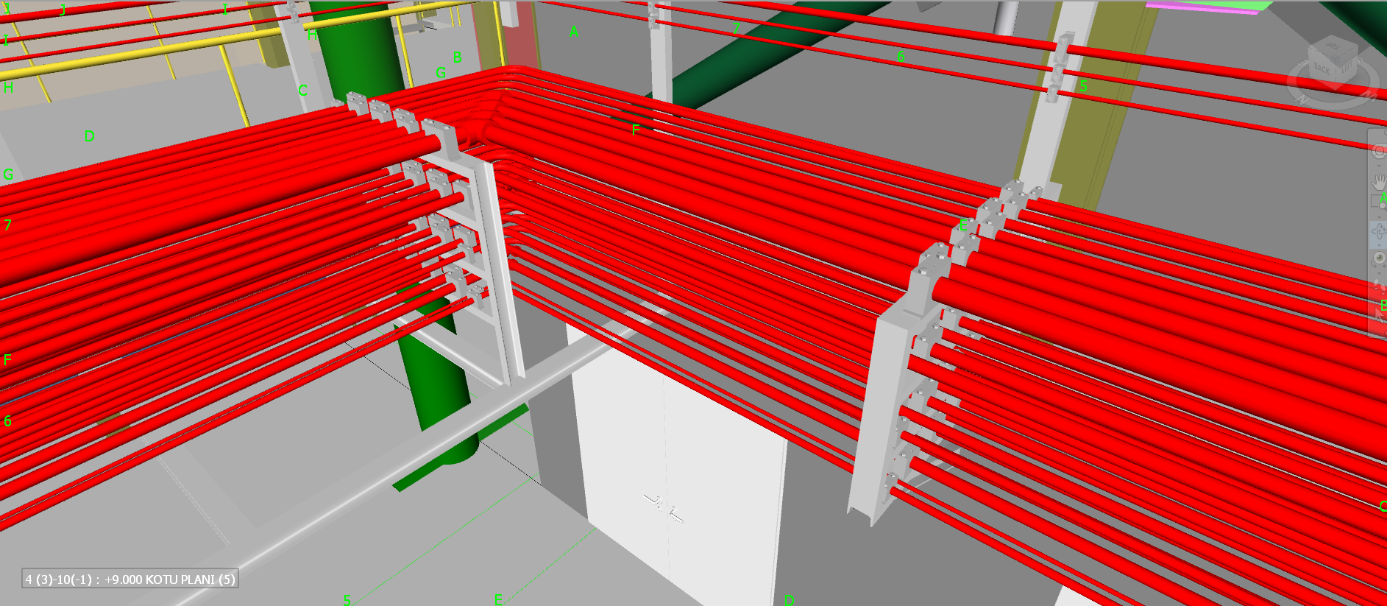

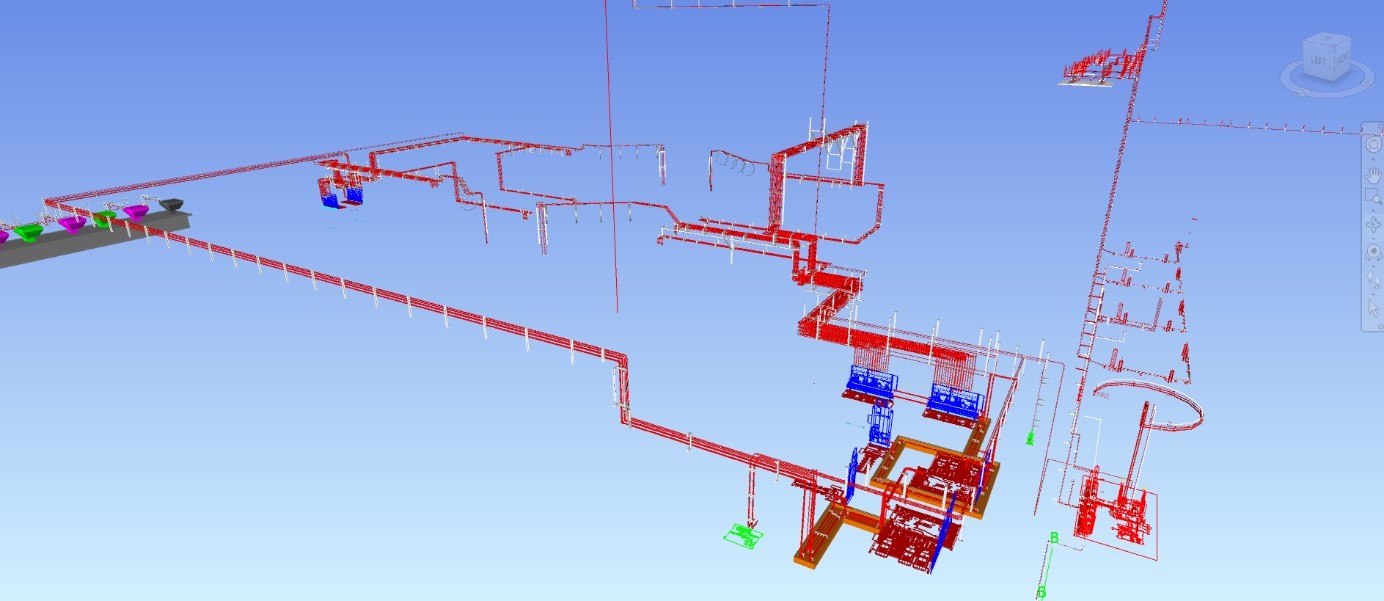

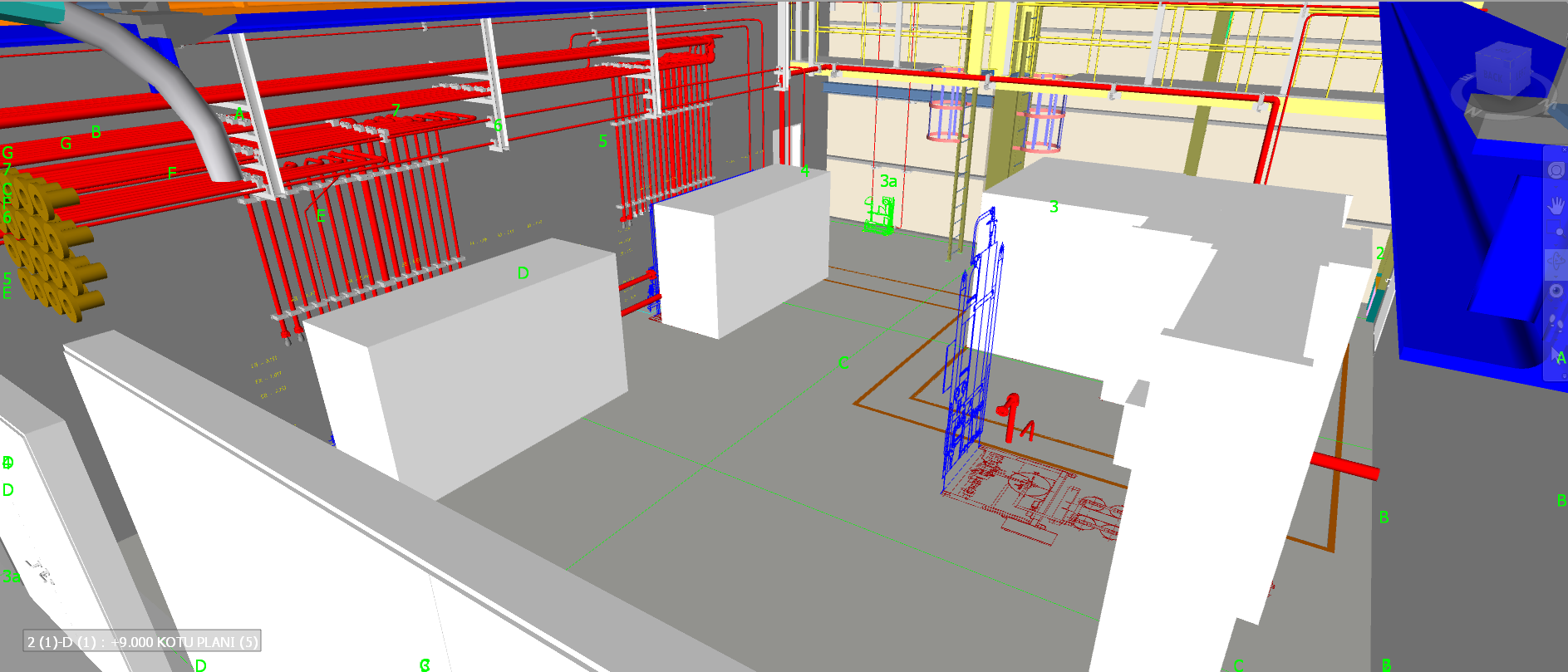

We have realized the piping of all hydraulic and grease lubrication lines of the project, which will be the highest capacity blast furnace in Turkey. Regions covered by the project are foundry, peak charging, charging facility, gas cleaning and stoves. In all lines of the project, 316L stainless material were used. Socket welding method was used as pipe assembly technique.

Certified materials were used in all pipelines with a diameter range of 8-139.7 mm and a total of 15 km of pipes were installed. With the completion of the pipe installation works, we carried out the pressure tests, pickling and flushing processes of all lines.

Before the fieldwork, the detailed engineering of the entire project was carried out. With these route drawings, the correct material amounts were determined and conflicts that may occur during the work in the field were prevented.

-

Sector

Iron & Steel

-

Year

2023