Plastic Injection Robots

Plastic Injection Robots

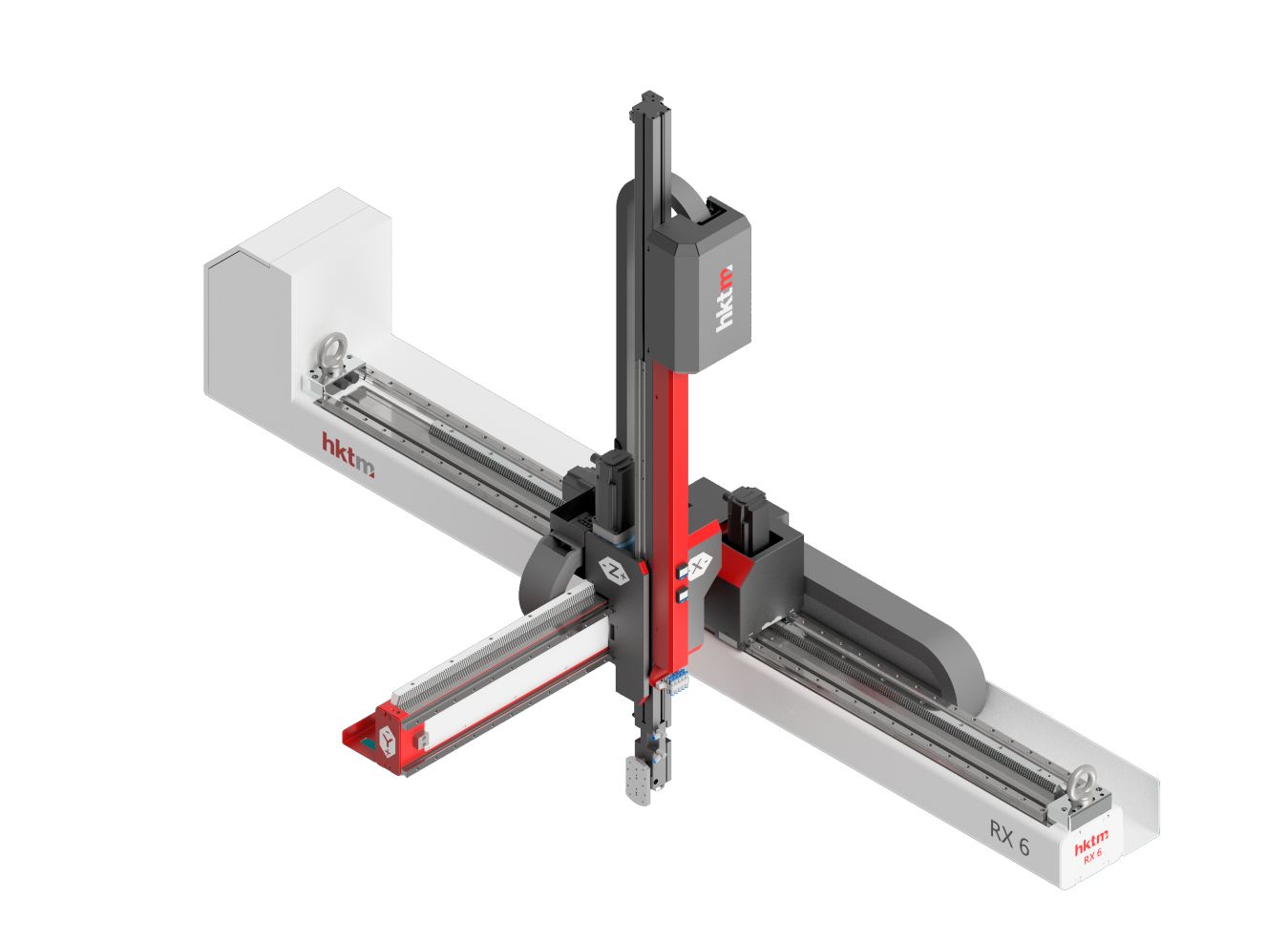

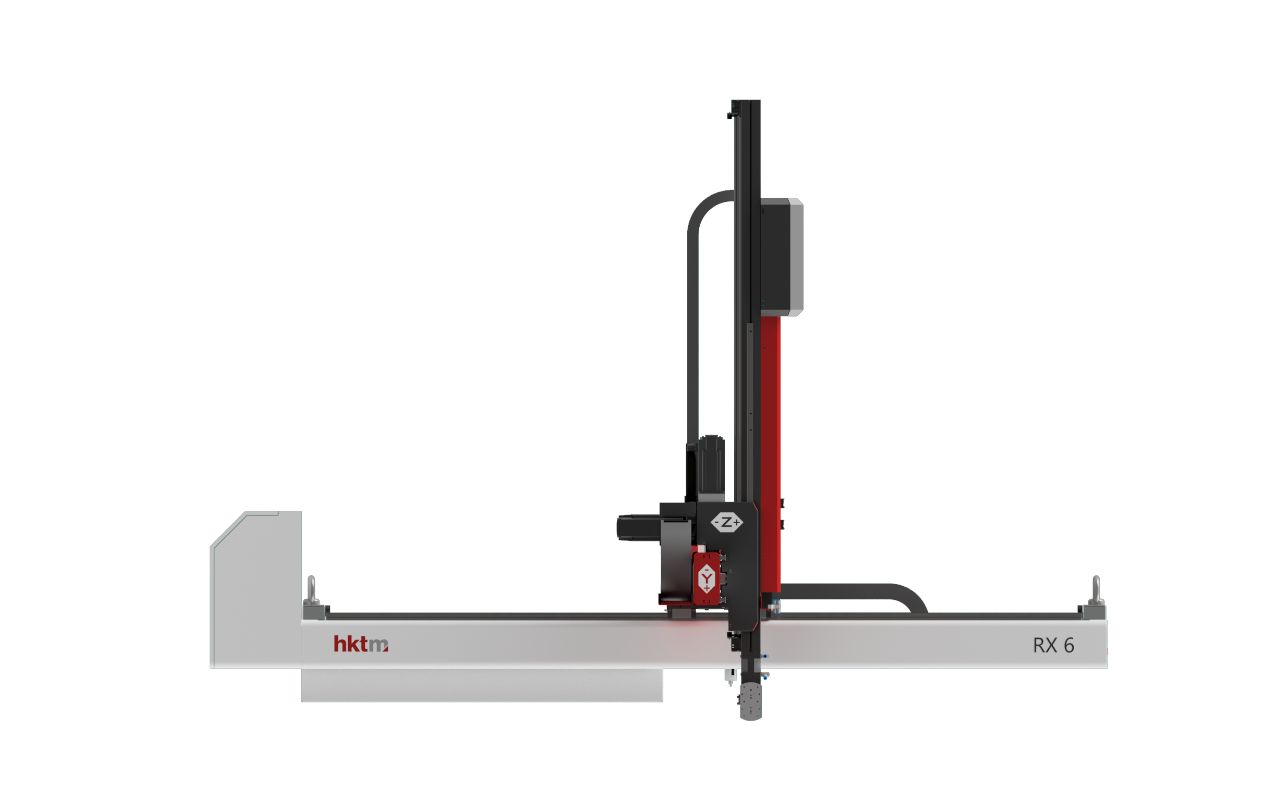

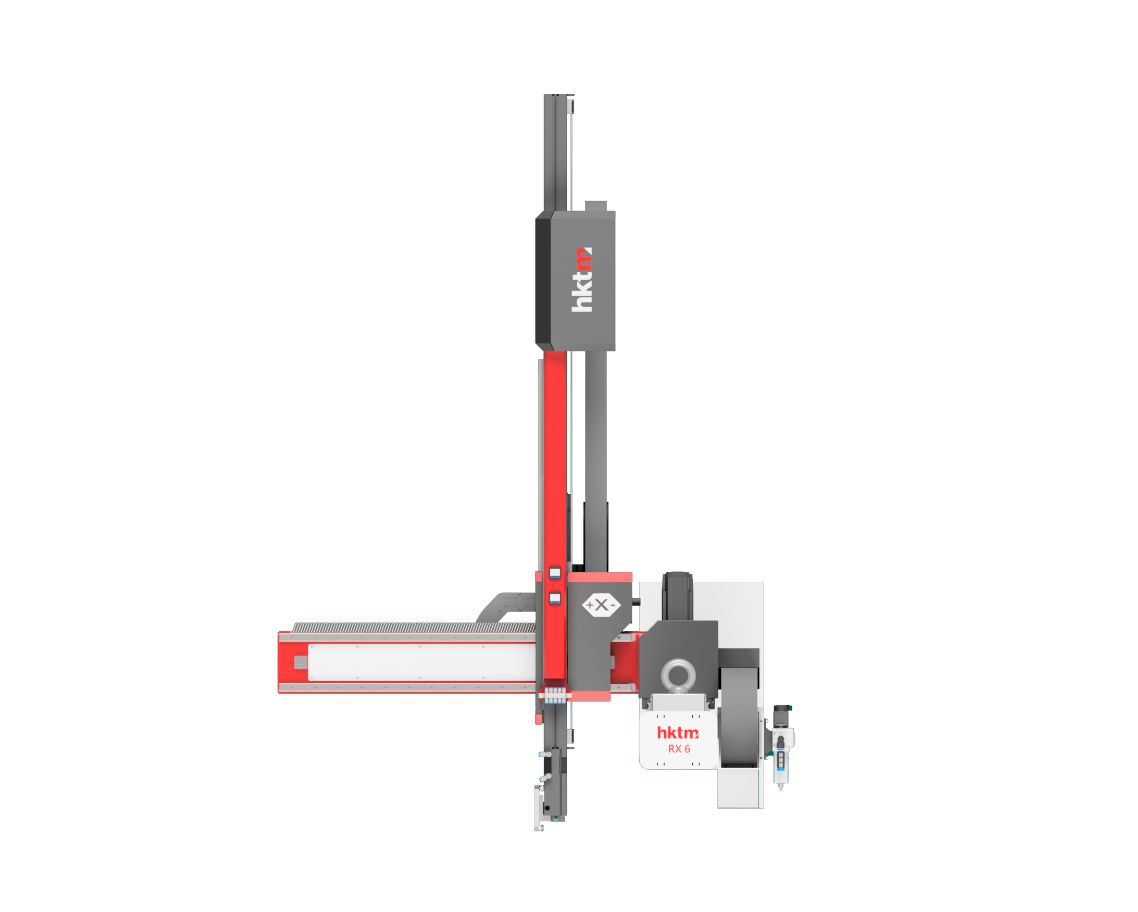

RX6 robot model ensures that the production is optimum and the cycle is serial with standardized stroke lengths and axis spees for small and medium sized injection machines.

- Payload (kg): 6

- Vertical Stroke Y Axis (mm): 600 / 800 / 1000 / 1200

- Control flexibility with Tablet PC

- The servo motor used in RX6 robot model is a Bosch Rexroth product which provides movement freedom up to 36 axes.

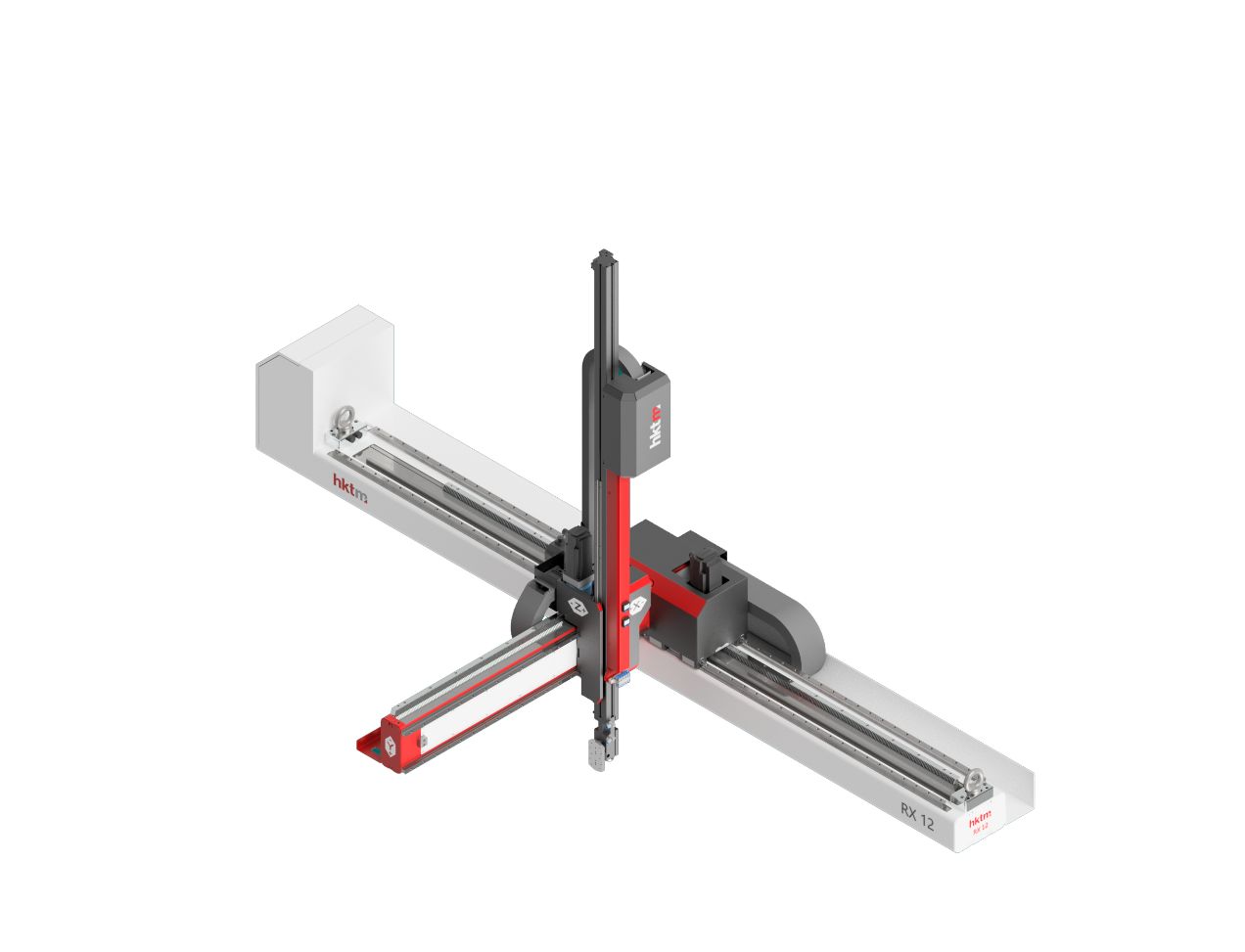

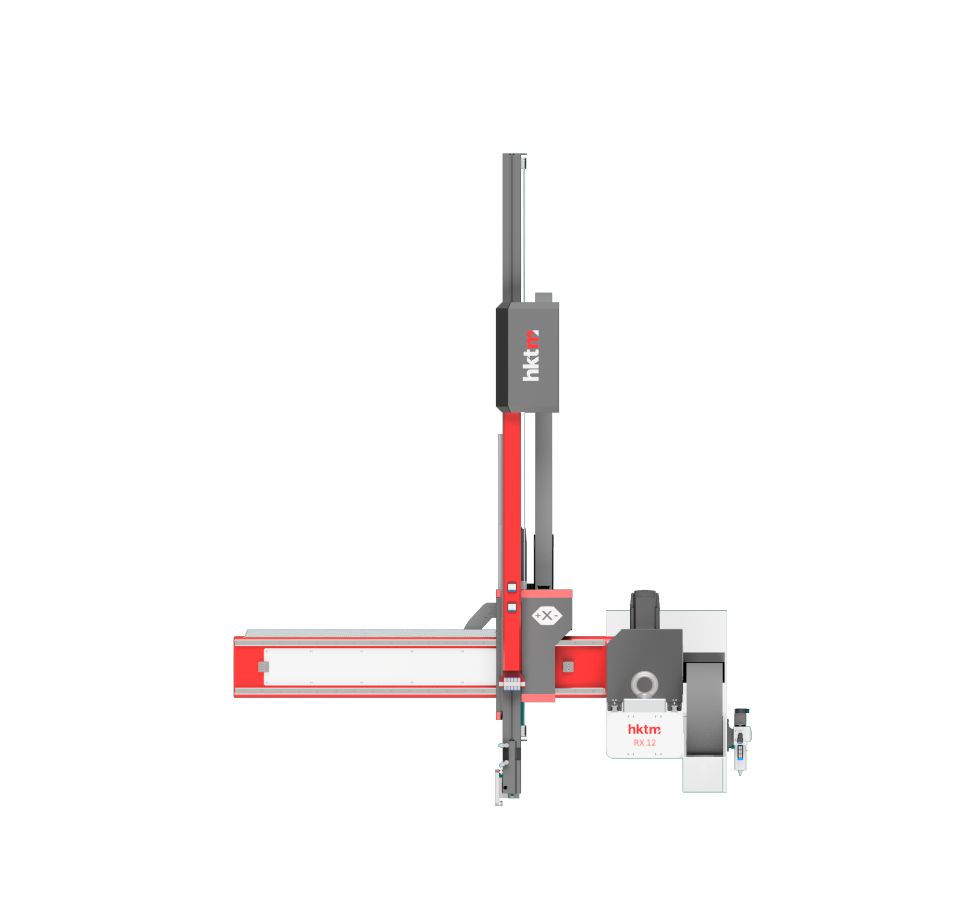

RX12 robot model has been designed for medium and large machinery tonnages. Optimized for picking operations.

- Payload (kg): 12

- Vertical Stroke Y Axis (mm): 1000 / 1200 / 1400

- Control flexibility with Tablet PC

- The servo motor used in RX6 robot model is a Bosch Rexroth product which provides movement freedom up to 36 axes.

RX12S robot model has been designed for medium and large machinery tonnages. It has a specially designed double rail vertical axis for high precision applications needed in IML and metal insert applications.

- Payload (kg): 12

- Vertical Stroke Y Axis (mm): 1200 / 1400 / 1600

- Control flexibility with Tablet PC

- The servo motor used in RX6 robot model is a Bosch Rexroth product which provides movement freedom up to 36 axes.

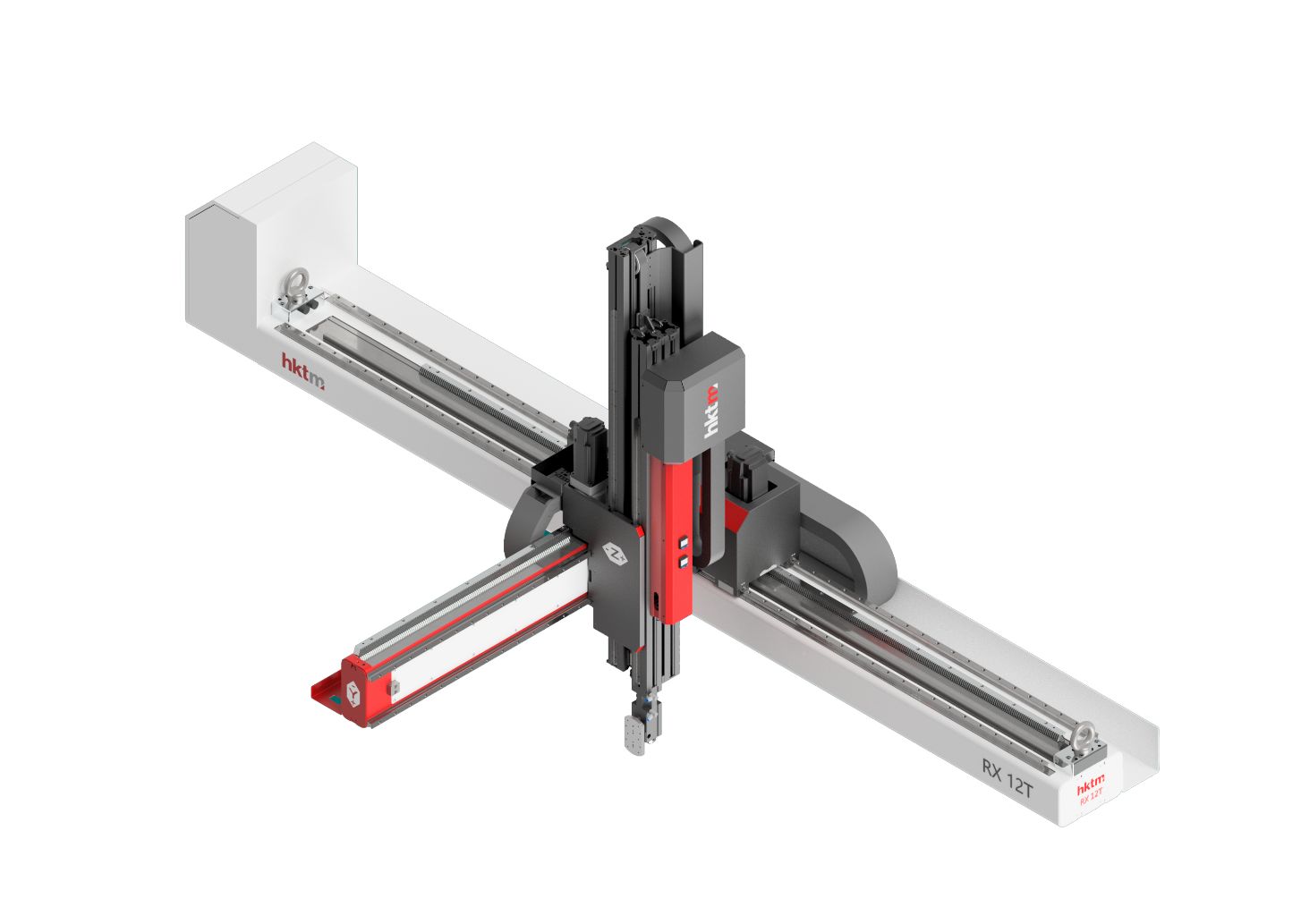

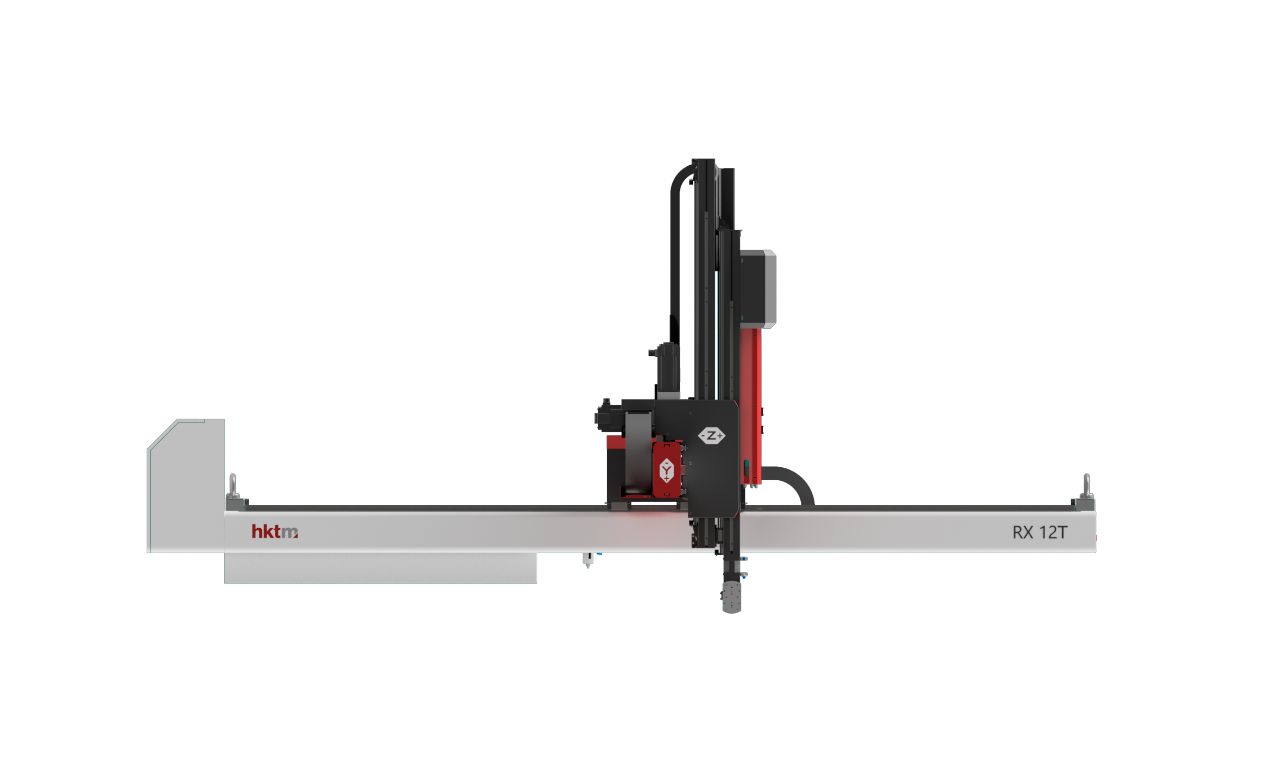

RX12T robot model with telescopic vertical axis is designed for low ceiling production areas, suitable for medium and large machinery tonnages.

- Payload (kg): 12

- Vertical Stroke Y Axis (mm): 1200 / 1400 / 1600

- Control flexibility with Tablet PC

- The servo motor used in RX6 robot model is a Bosch Rexroth product which provides movement freedom up to 36 axes.

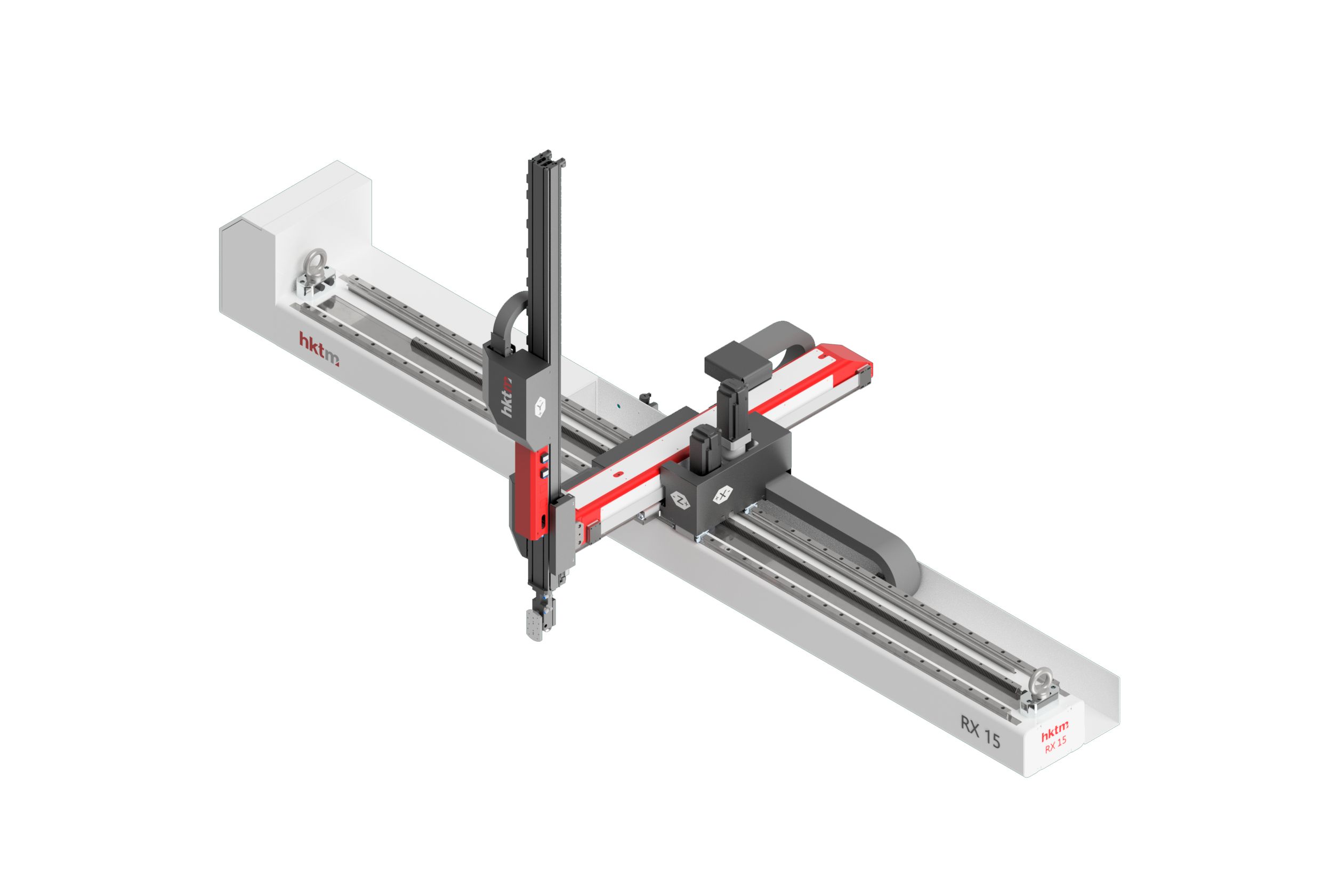

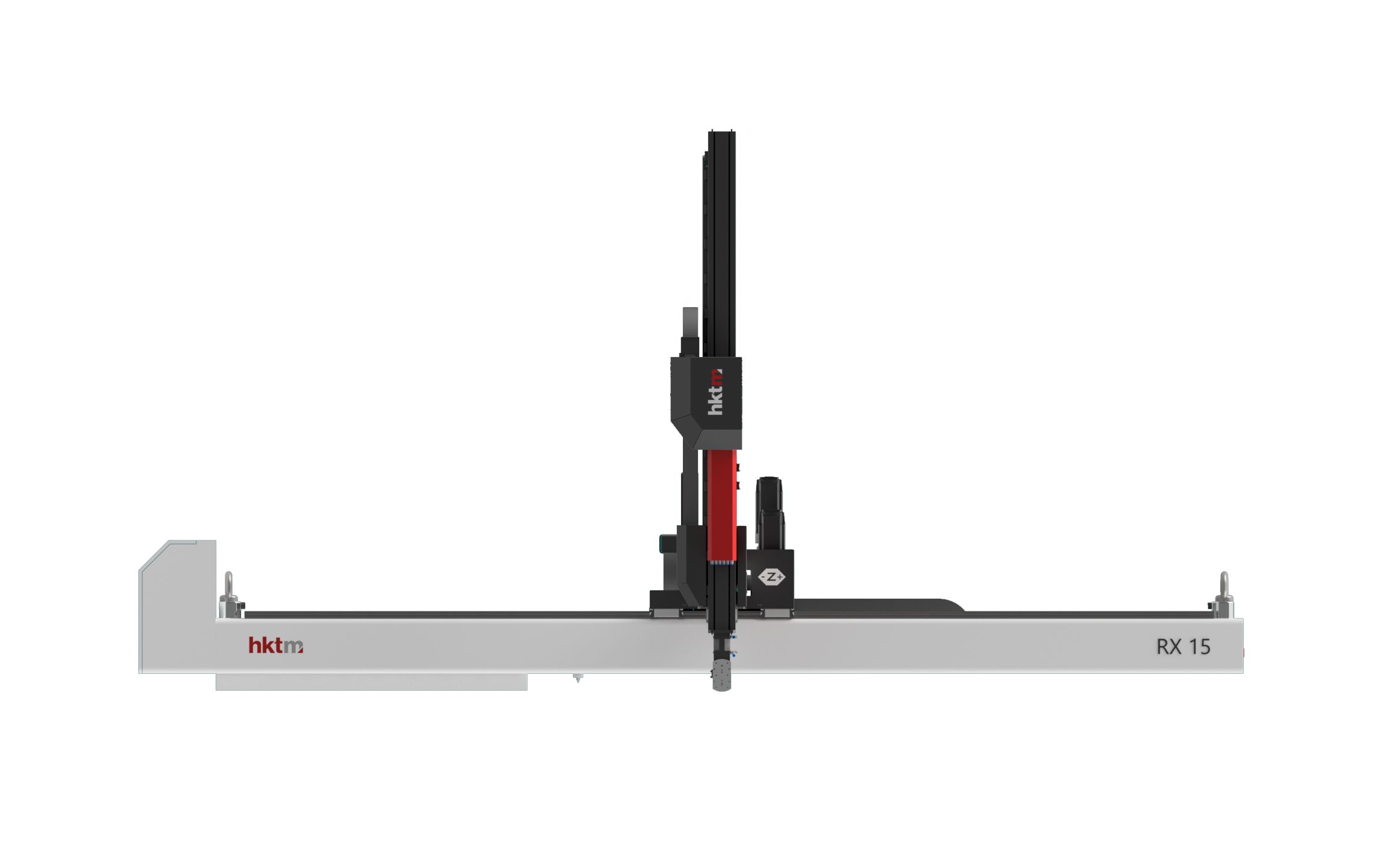

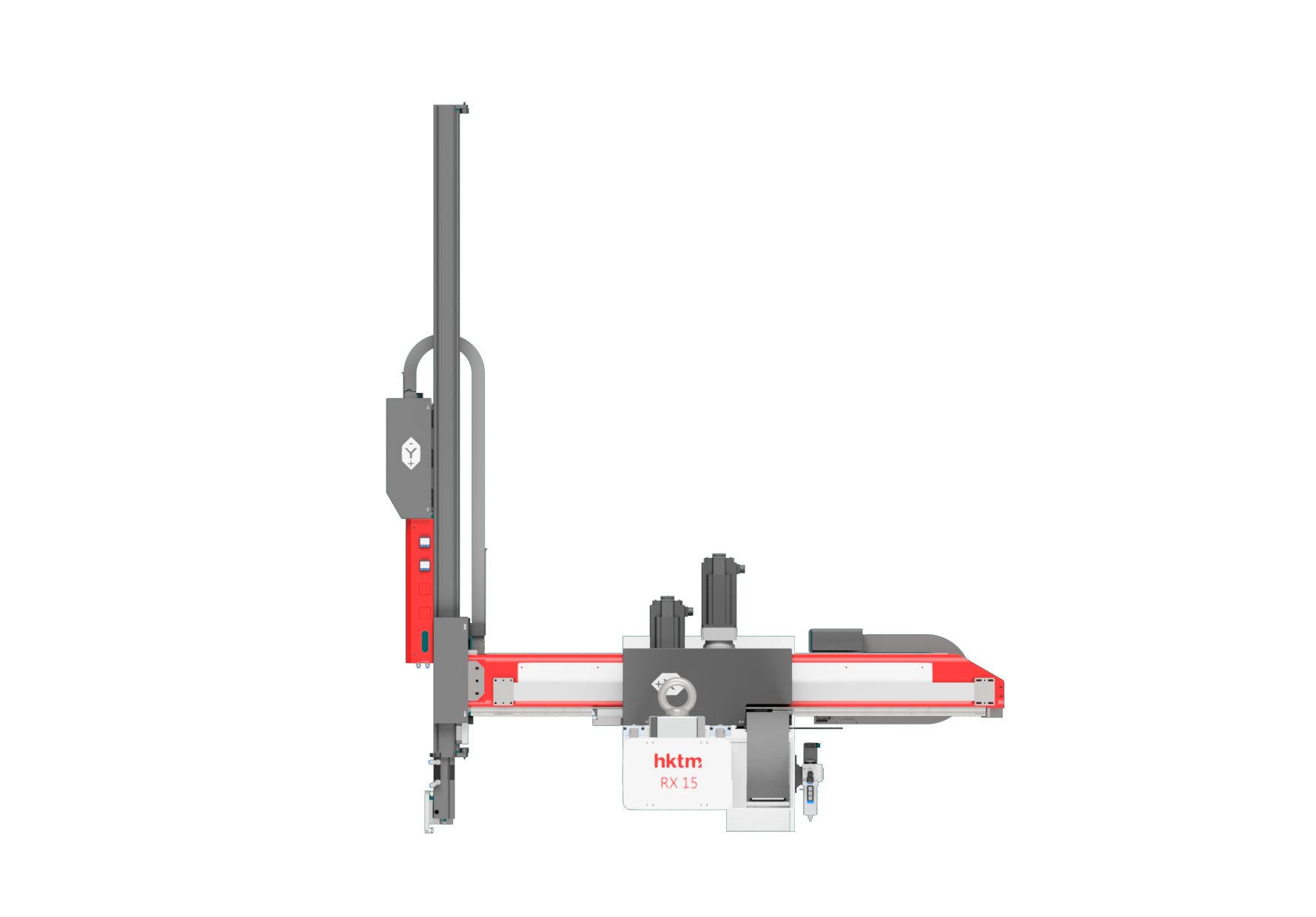

RX15 robot model is designed for medium machine tonnages. The movable X axis assures a reduction in the moment on the axis which ensures that injection applications with heavy parts and holders are carried out more safely.

- Payload (kg): 15

- Vertical Stroke Y Axis (mm): 1400 / 1500

- Control flexibility with Tablet PC

- The servo motor used in RX6 robot model is a Bosch Rexroth product which provides movement freedom up to 36 axes.

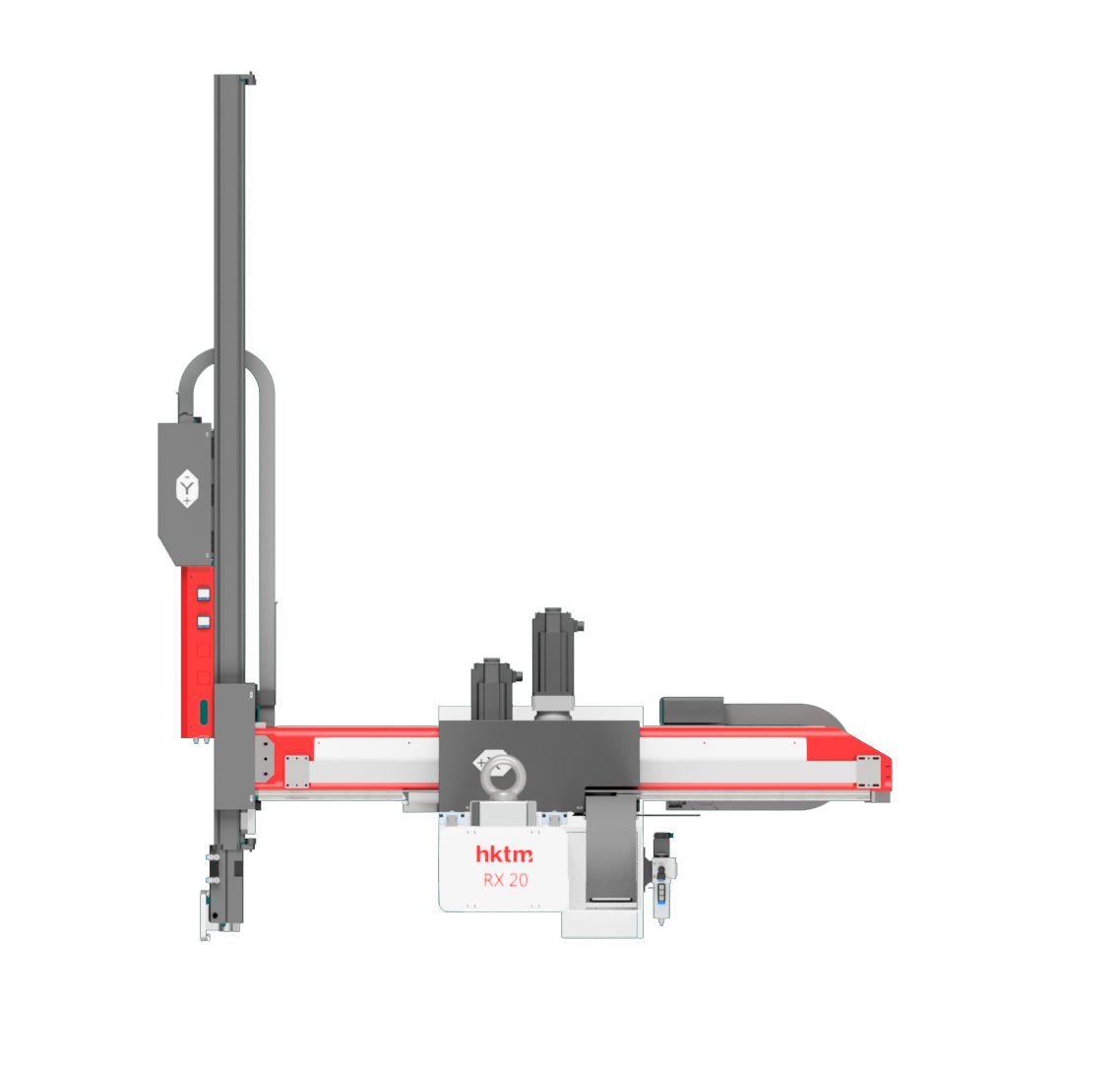

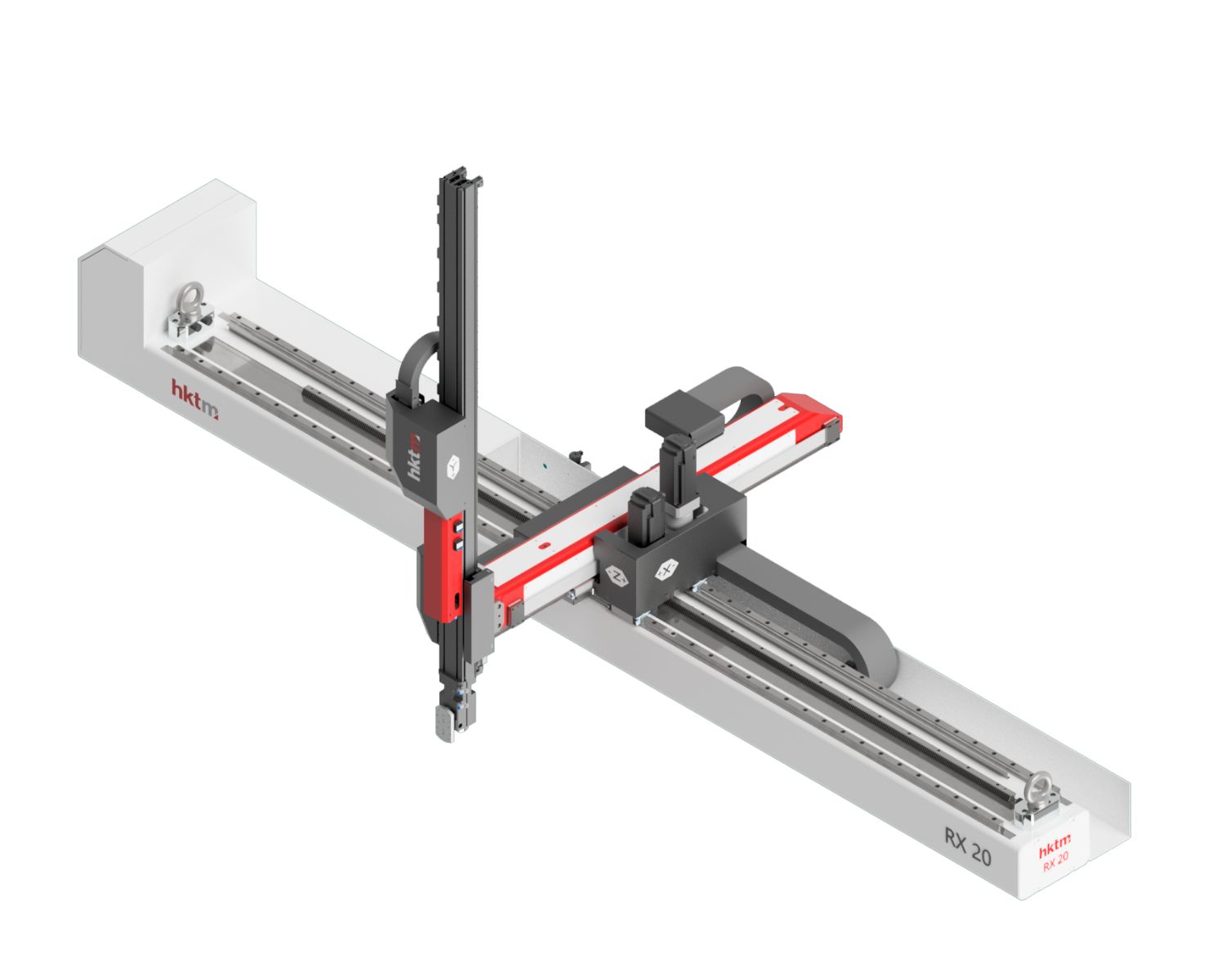

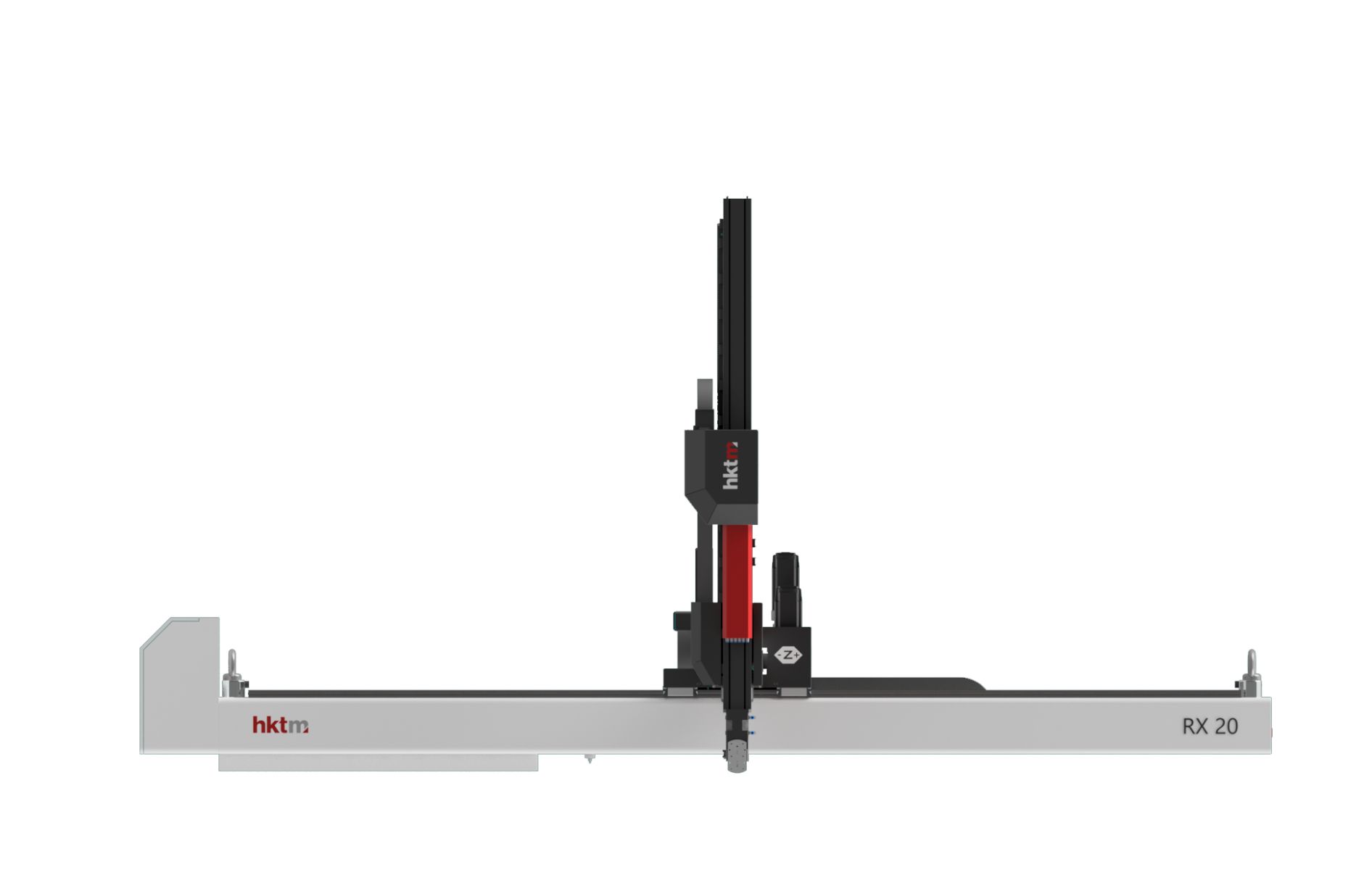

RX20 robot model is designed for medium and large machine tonnages. The movable X axis assures a reduction in the moment on the axis which ensures that injection applications with heavy parts and holders are carried out more safely.

- Payload (kg): 20

- Vertical Stroke Y Axis (mm): 1400 / 1500 / 1600

- Control flexibility with Tablet PC

- The servo motor used in RX6 robot model is a Bosch Rexroth product which provides movement freedom up to 36 axes.

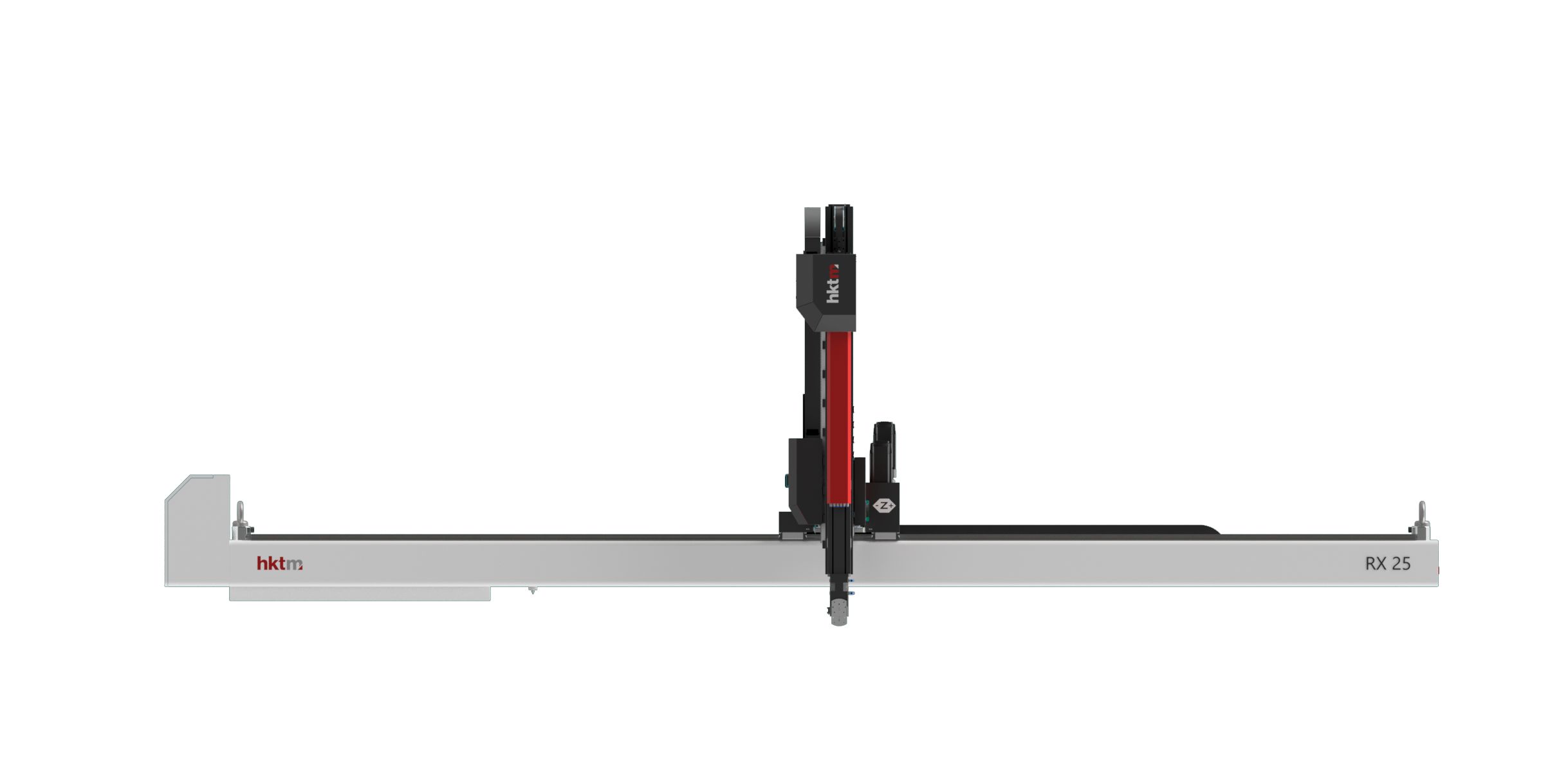

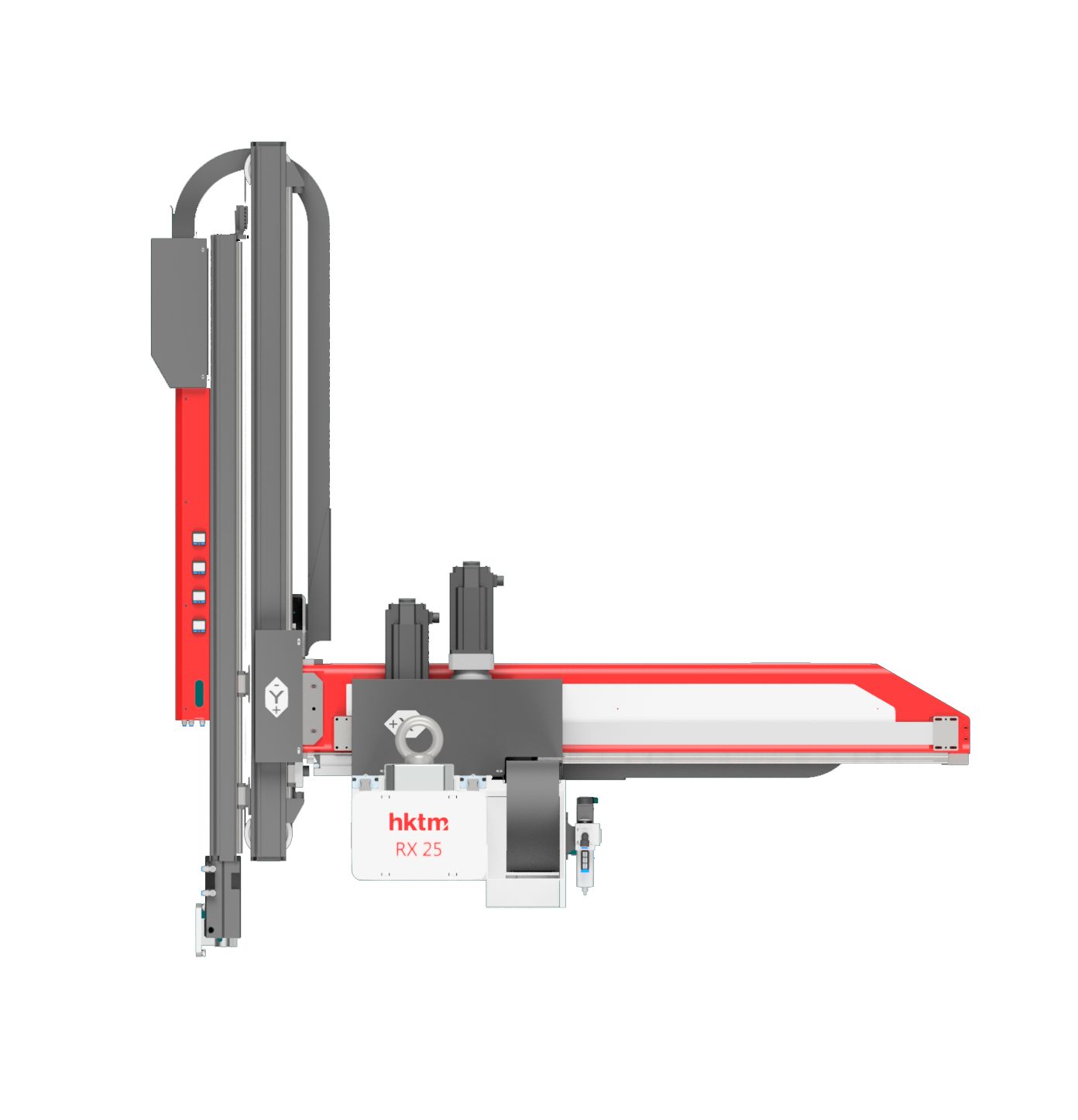

RX25 robot model has been designed for medium and large machine tonnages. The movable X axis assures a reduction in the moment on the axis which ensures that injection applications with heavy parts and holders are carried out more safely.

- Payload (kg): 25

- Vertical Stroke Y Axis (mm): 1600 / 1950

- Control flexibility with Tablet PC

- The servo motor used in RX6 robot model is a Bosch Rexroth product which provides movement freedom up to 36 axes.

Advantages

- The dynamic servo motors, high precision linear movement components used and engineering of Bosch Rexroth enables RX series robots to perform at constant 80placement, IML (in-mould labelling) and quality assurance applications.

- With the internationally accepted software base, RX series robots integrate accurately and easily into all plastic injection machines and applications; therefore, complete the machine.

- Absolute encoder servomotors are used in all axes of RX series robots which allows them to remember their position after power cuts; hence, time losses are prevented.

- In the robotic axes where racks are used, the noise during the movement is kept optimal using helical racks.

- Proven rail trolley groups used in RX series robots result in maximum precision movement and rail trolley wear times.

- The torque control (X Free) feature existing on all three axes prevents damage to the axes of RX series robots during the product picking process.